Membrane Filtration

HOMOGENIZATION

OVERVIEW

Proven Systems and Dedicated Specialists

Membrane filtration is a series of technologies for separating components from a liquid primarily by molecular weight, but also by size or charge. It is used in the dairy and plant-based industries, for separation of milk, whey, and plant-based components into smaller fractions, which become the building blocks for innovative recipes. Membrane filtration is a highly sustainable, versatile, and proven process designed to increase the production capacity. It allows for higher yields and less waste by valorization of sub product and recovery of water.

The separation is determined by membrane characteristics (pore size) and molecular size of the individual components present in the liquid. The pressure driven molecular separation process is used to obtain:

As a leading global provider of membrane technology to the dairy and plant-based industries, SPX FLOW offers a range of membranes and operates with four key technologies:

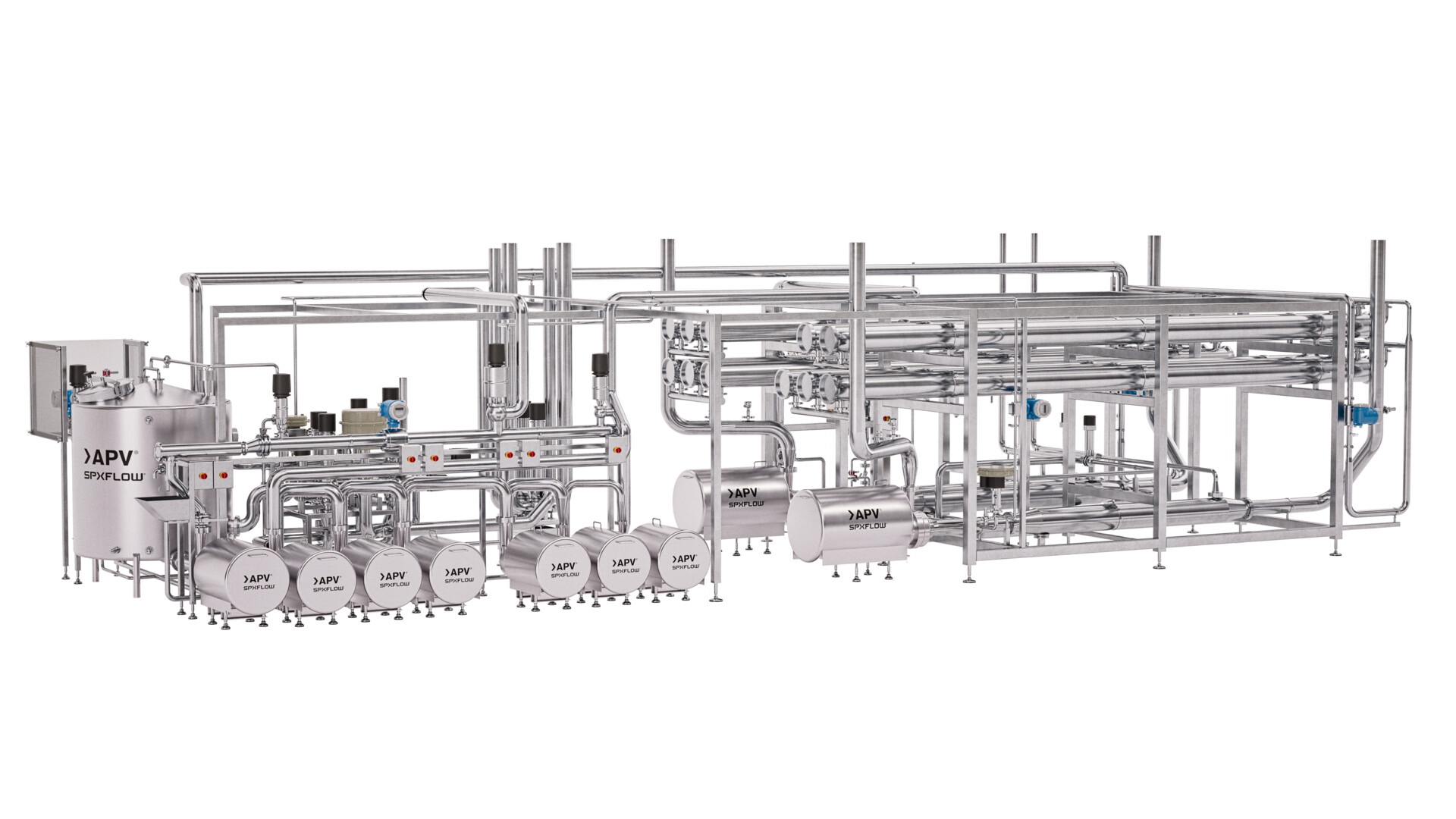

Our membranes are available in both plug-and-play configurations and fully customized solutions. We offer a range of options based on technical specifications, performance goals and operating costs. Options range from stand-alone to integrated systems that are automated to deliver optimal control and performance. Integrated in-line systems feature pre- and posttreatment for seamless integration with new or existing process lines.

The main advantages of membrane filtration include:

APPLICATIONS

*New applications constantly in development

MICROFILTRATION (MF)

Microfiltration is used in various dairy and plant-based applications for debacterization, fractionation, clarification and concentration of proteins using ceramic and polymer membranes. Microfiltration is based on a membrane with a very open structure allowing most dissolved substances to pass, while rejecting non-dissolved particles, bacteria, spores, and fat globules. Contingent on the application, MF membranes and process parameters are used to secure optimal performance of the plan

Membrane Filtration

ULTRAFILTRATION (UF)

Ultrafiltration for concentration of milk, whey and plant-based sources is a widely used concentration step in the process of making different whey, milk, or plant-based products. Additionally, UF concentration is used to produce fresh cultured cheeses such as cream cheese, feta and queso fresco with substantially higher yield.

Membrane Filtration

REVERSE OSMOSIS (RO)

At SPX FLOW we put customers at the heart of everything we do and our lifetime support starts by engaging with you early. We use our extensive experience in designing, building, supporting and upgrading to offer optimal homogenizer service solutions for our customers. When we design your products and systems, we don’t just look at what was done before - we look at how our existing systems operate in real-life.

EXPERTISE

SPX FLOW has decades of experience providing membrane solutions for the dairy industry. We strive to engineer technology that is integral in the production of all milk and plant-based products via a highly sustainable approach that reduces waste. The heart of our business is to combine sound economics with an optimized environmental footprint.

Our APV membrane filtration technology is the result and close cooperation with world-leading manufacturers of membranes and cleaning agents. This deep experience, combined with a range of technology solutions, means that our specialists recommend the most efficient membranes possible for any given application, while also offering dedicated support and expert service. Other reasons to choose SPX FLOW include: